Since 2018 each Indusvent Regional Office has taken ownership for the real time monitoring of the operating performance of their regionally installed systems.

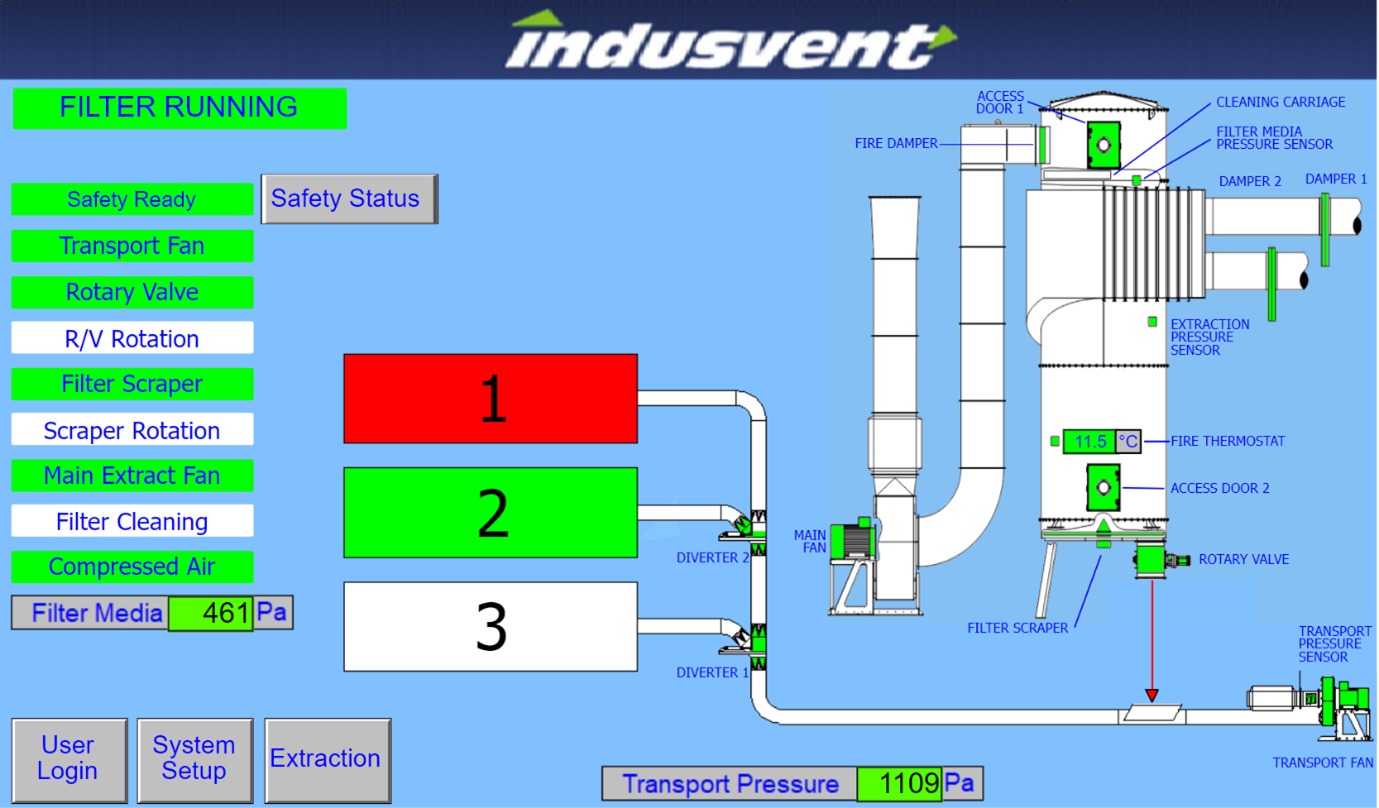

Now as standard for all Super-Blower filter system installations, the Siemens Control Panel

The real time monitoring checks include the temperature of all Variable Speed Drives, Control Panel Enclosure and motors and the torque level of all geared motors.

This highlights a potential issue well in advance of it becoming a critical breakdown issue minimising loss of production.

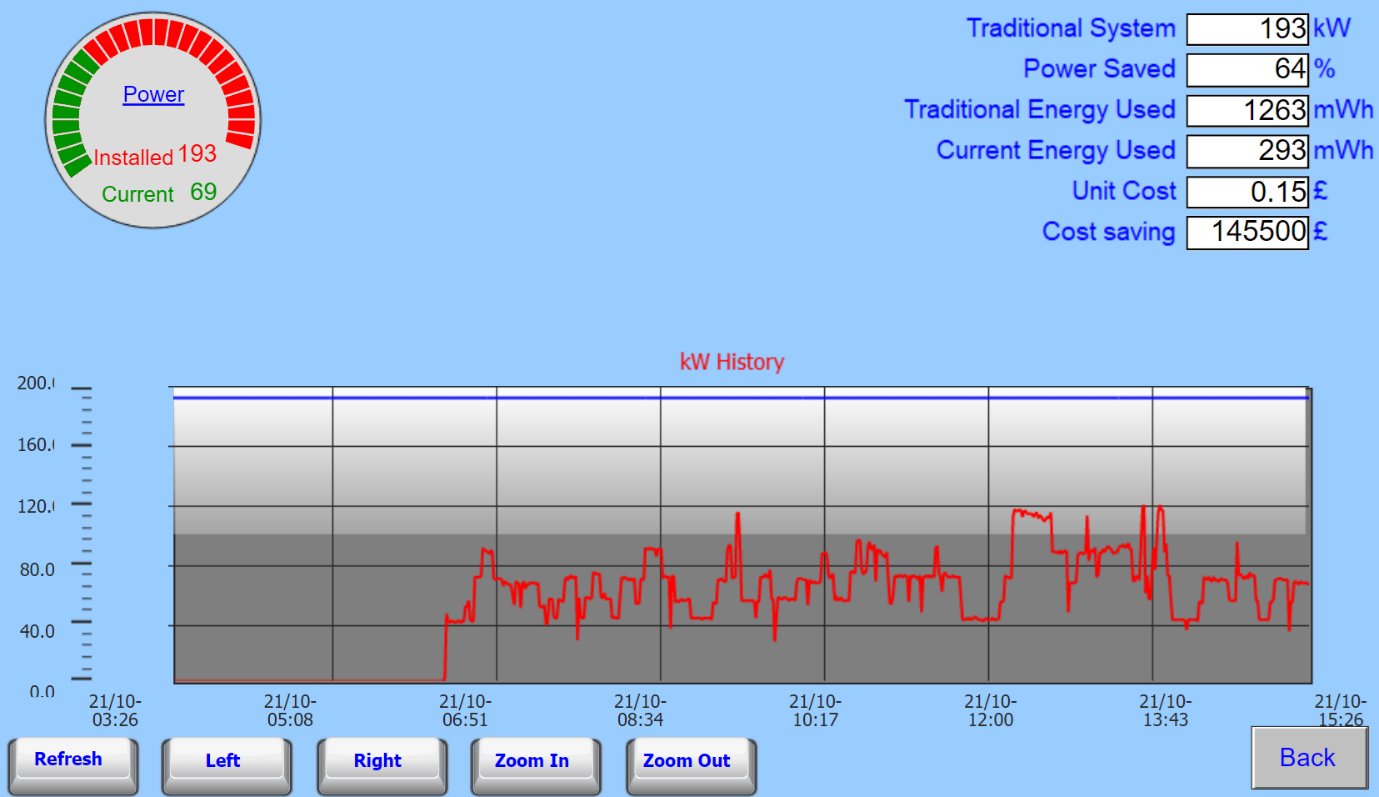

The checks also monitor the filter media condition and the accumulated electrical energy cost savings, this is particularly interesting when comparing our Energy Saving Super-Blower with the equipment that it has replaced.

It has proven to be an extremely valuable preventative maintenance tool for many of our customers, many of which are operating 24 hours a day 7 days a week.

For some of our customers it can be an effective tool to log production cycles, especially when each machine is served via a dedicated duct line with automatic slide damper.

The data is stored in a historical time graph, the latest additions to the Indusvent Remote Monitoring System are dust particulate emission level and motor vibration along with trailer monitoring so that you know what trailer was being loaded and when.

If you want more information on Indusvent Remote Monitoring System or one of the many extraction systems Indusvent offer, then visit our website @ www.indusvent.com contact us by email: mail@indusvent.com or call us on 0333 9967 333