Project Details

A Scottish leader in Offsite Manufacturing since their launch in 2010 have invested in an Indusvent Blower filter BF55-4 to specifically take care of dust on plaster board based cutting processes. This project involved detailed planning prior to the installation as it also meant we had to make significant modifications to and existing system to allow all the customers chop saws to be on their extraction system. This customer will now benefit from free remote support and weekly reports highlighting any system concerns, this allows us to be proactive to any breakdown rather than being reactive.

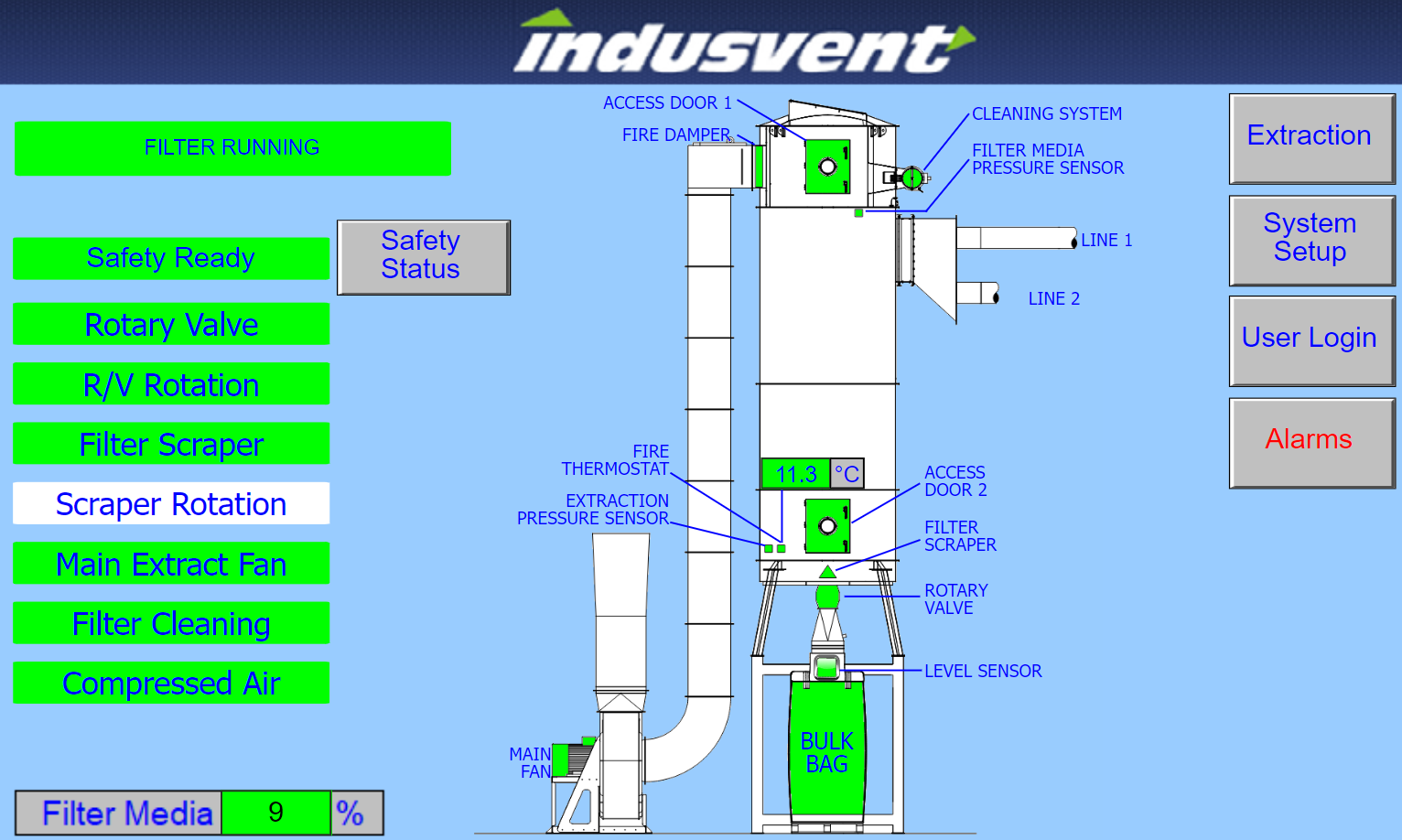

The filter is raised on a 2.5m frame and the waste drops via a rotary valve into a 2m3 bulk bag below, this is an extremely efficient method as you have no power consumed by a 2nd fan or scraper conveyor.

This whole system is controlled by a Siemens PLC, Touch screen HMI and a remote router used by @indusvent to carry out weekly monitoring of the system to ensure a smooth extraction operation for the business.

MAIN SUCTION DUCT LINES: 1

MAIN FAN WITH VARIABLE SPEED DRIVE: 22kW

OPERATION: 2 SHIFTS 5 DAYS