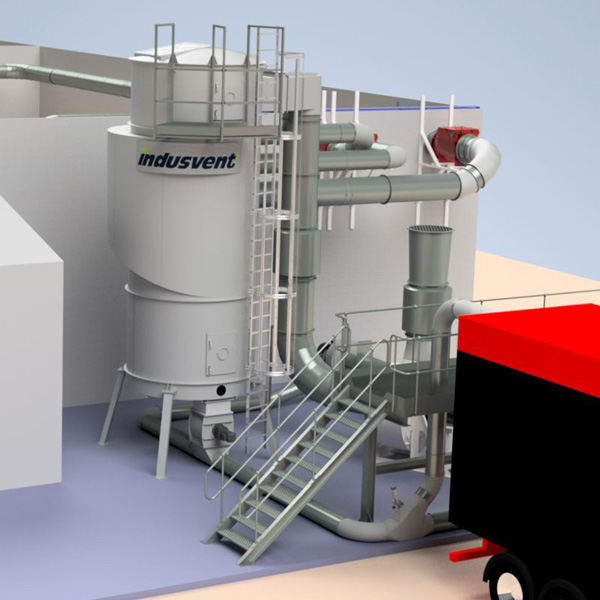

The UK’s leading garden room and climbing frame designer, manufacturer and supplier have chosen Indusvent to Design, Supply and Install the new ATEX certified dust extraction system for their latest factory in the North of Scotland. This top of the range system comprises of an Indusvent Super Blower 90-4 filter, a JK70MTD-55kW direct drive extraction fan on the clean air side of the filter, waste material leaves the filter via a B500 heavy duty rotary valve and is then blown into 1 of 2 trailers which will automatically switch based on transport pressure using our direct drive T300D transport fan, we have also added a JK50s Rotary valve on a 2nd filter outlet to allow the customer to look at producing their own briquettes in the future. The ducting system comprises of 3 independent lines, each with machine controlled auto dampers and explosion isolation valves.

With Indusvent econtrol the extraction fan will only run at the speed required depending on the number of lines that are open which means this customer is only paying for energy when they need it and have also created a much better working environment for operators setting up machines. With clean up points included at every machine as standard this factory will be spotless without the use of brushes which can re-introduce fine dust back into operators breathing zones.

The full system is protected with a Grecon BS-7 Spark Detection System, the design, purchase and installation of which was all managed by Indusvent, all that is required from the customer is Electrical supply, Air Supply and a network connection as Indusvent take care of everything else.

All of the above will be monitored using the Indusvent remote monitoring system allowing us to keep an eye on your extraction while you are busy doing what you do best, if we spot anything worth talking about we will send you a weekly update all free of charge.

For full details see link below