Direct Doors

Home

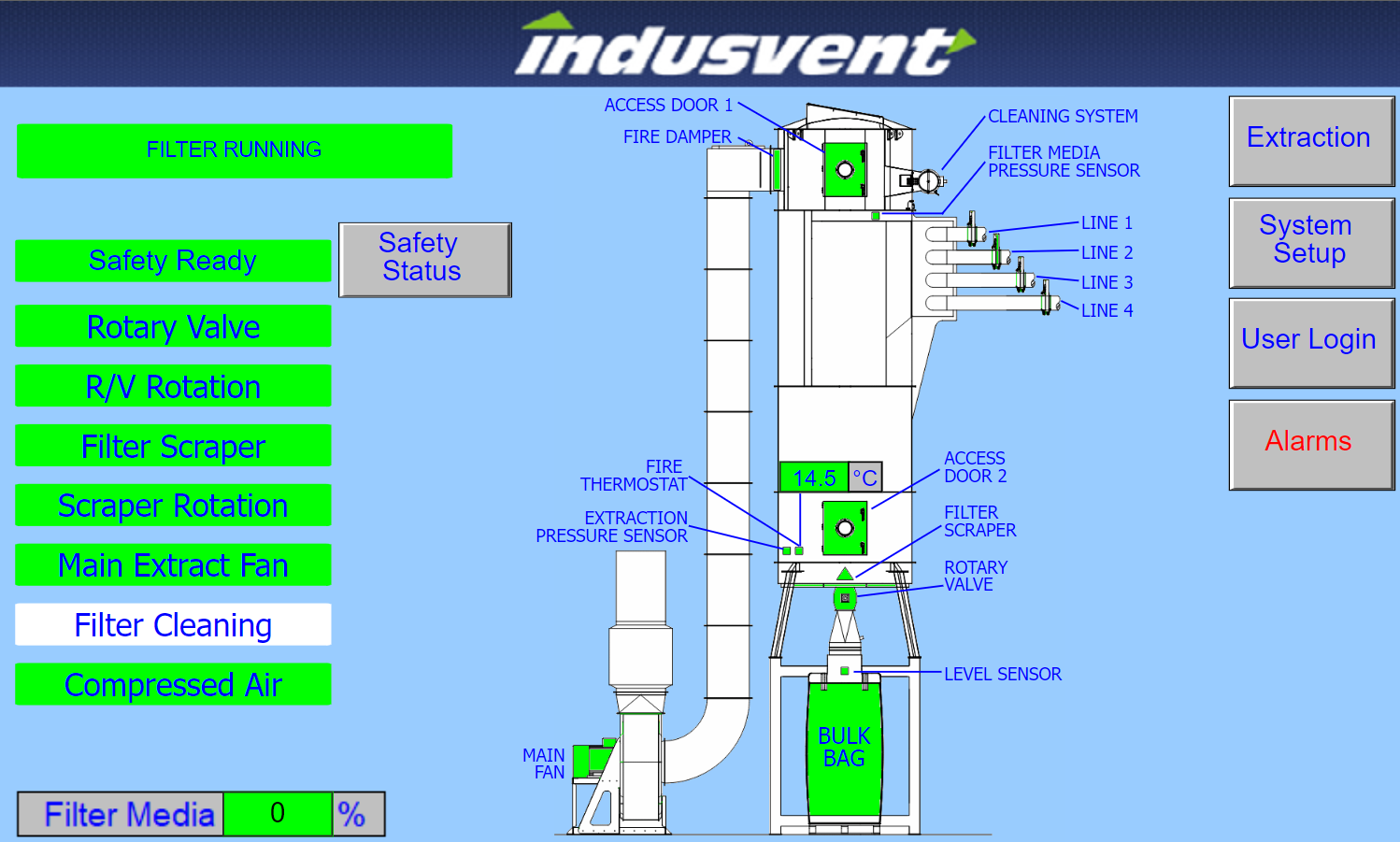

When directdoors.com decided to move into the world of manufacturing, they entrusted Indusvent to Design, Supply and Install our Blower Filter model BF55-4, the system was designed with 4 independent extraction lines connected to 10 production machines, all lines fitted with pneumatic slide dampers, this allows us to only open the lines that are in use and to run the extraction fan at the correct speed for the number of lines open making the system extremely energy efficient. This system design ensures that the transport velocity is always maintained and that no material will drop out in the main lines and lead to blockages. The filter is raised on a 2.5m frame and the waste drops via a rotary valve into a 2m3 bulk bag below, this is an extremely efficient method as you have no power consumed by a 2nd fan or scraper conveyor.

This whole system is controlled by a Siemens PLC, Touch screen HMI and a remote router used by @indusvent to carry out weekly monitoring of the system to ensure a smooth extraction operation for the business.

MAIN SUCTION DUCT LINES: 4

MAIN FAN WITH VARIABLE SPEED DRIVE: 37kW

OPERATION: 40 HOURS

Michael Froude and the directdoors.com team have been a pleasure to deal with from concept to completion and know that the Indusvent regional office based in Grangemouth is only 20 mins away if they need us.