One of the UK’s leading manufacturers and distributors of quality timber frame panels for over 50 years have invested in 2 x Indusvent Blower Filter 55’s (Model BF55-4) to replace their old, tired, and inefficient positive pressure extraction systems. The first being commissioned October 2023 and the second BF55 filter system commissioned January 2024.

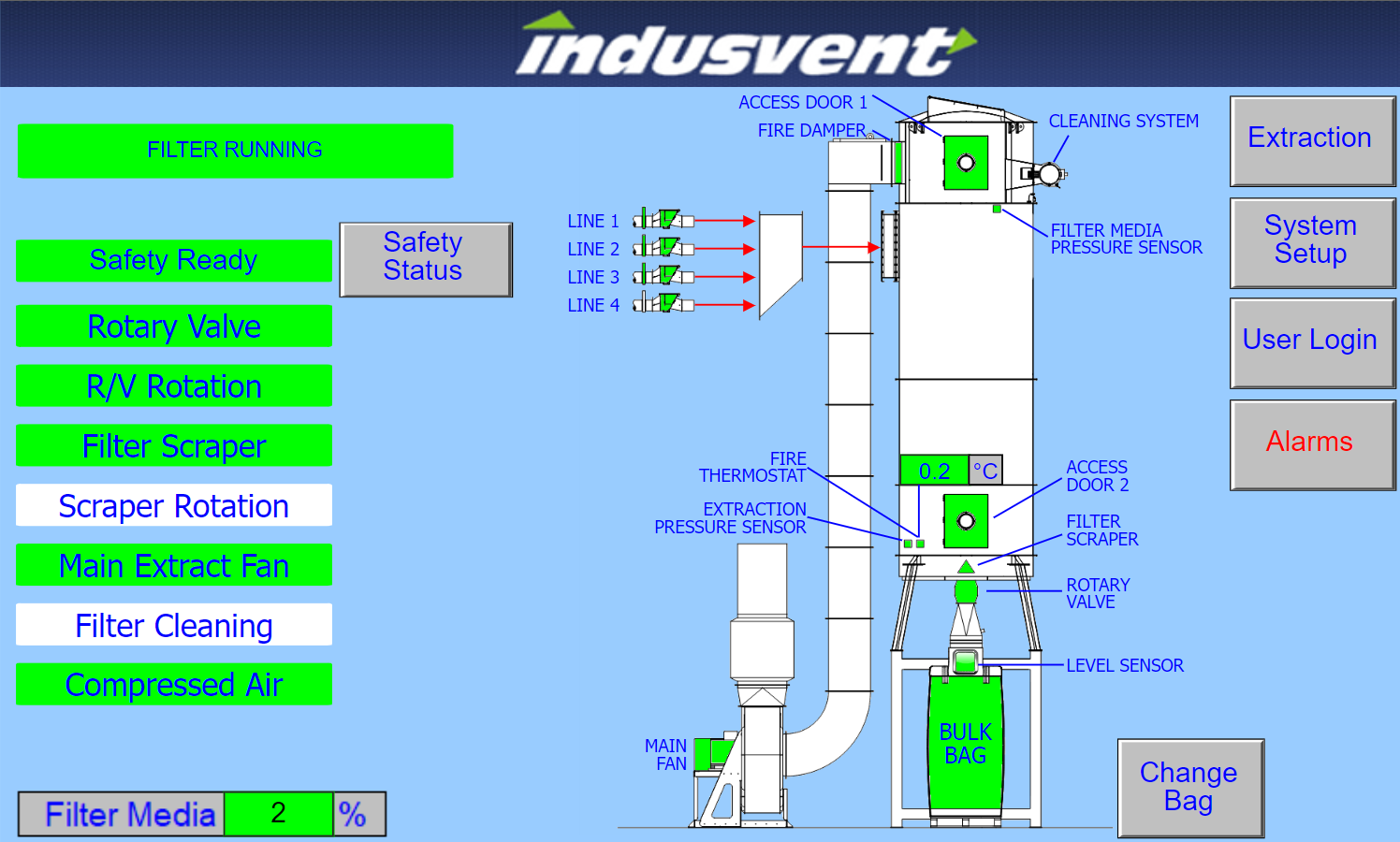

This second BF55 will provide negative pressure extraction to 8 classic woodworking machines, a Masterwood CNC Router and a Weinig Moulder, but only consuming power for what is running right now thanks to our intelligent Indusvent E control system, automatically sensing the extraction pressure and adjusting the extraction fan speed to maintain the extraction pressure, this ensures that we maintain transport velocity and don’t have any material dropping in the main line due to air starvation. The waste from the system is being dropped into a 2m3 bulk bag via a Rotary valve, our systems include a bag change feature to allow bag change while the extraction is still running to reduce machine downtime, we can even send you an email or text message to let you know you need to swap the bag over.

With the fan on the clean air side of the system it will never come into contact with the shavings/sawdust so will never wear out or cause the fan casing to wear yet another big saving over the 30 years this system will be in place.

This highly efficient dust extraction system will stand them in good stead for many years to come, energy saving low cost of maintenance and reliability are just some of the many benefits of this system.

We will now remotely monitor this system on a weekly basis (free of charge) to ensure there are no significant changes to pressures, temperatures or torques that suggest the system is in need of attention, this proactive approach to condition monitoring ensure that over 100 systems in the UK that we monitor on a weekly basis can run 365 days a year if required.

Comment from the customers Head of Engineering

“We’ve dealt with Indusvent for many years, and we know exactly what we are getting, which is safety being the number one priority, quality equipment, extensive planning where nothing is left to chance and the overall professionalism of everyone at the company from the sales office, CAD designers to the installation team who are a credit to the company. All these things combined mean we know we will be getting a quality product and installation that is designed and installed with safety being paramount”.

If you would like to know more about the BF55 or are interested in purchasing a market leading highly efficient extraction system, then don’t hesitate to get in touch.