The system is now fully commissioned, with the customer and the machine supplier both extremely satisfied with the final results.

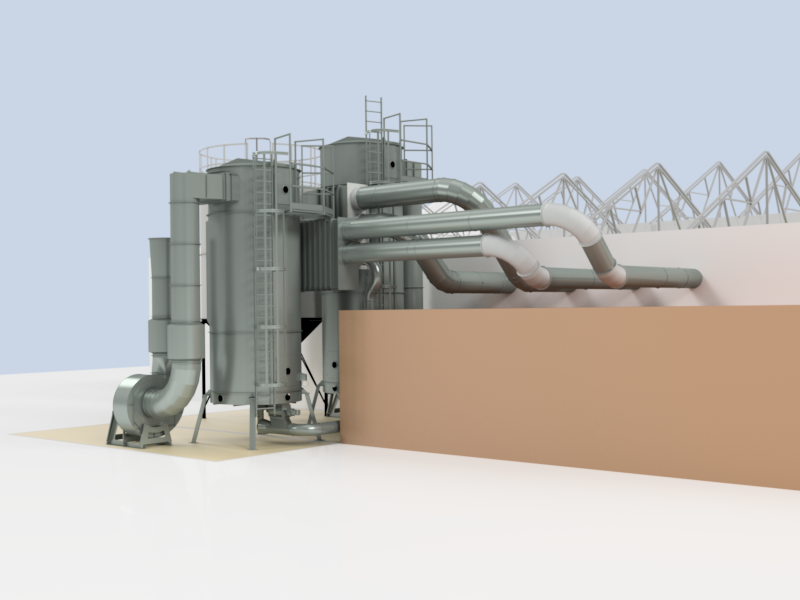

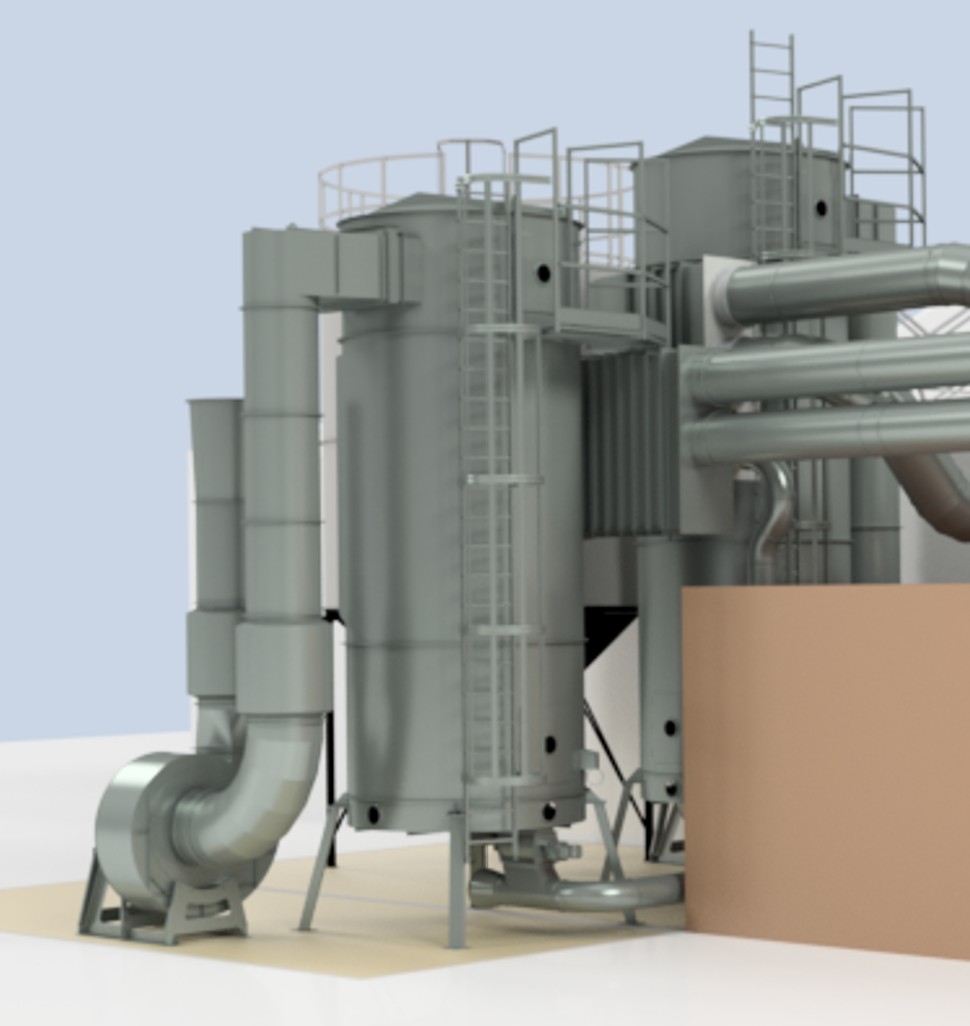

This top of the range system generating up to 34,000m3/hr, comprises of an Indusvent Super Blower filter reference 90-4.0, a JK70MTD-55kW direct driven, inverter-controlled, extraction fan, located on the clean air side of the filter. The collected dust is discharged via a singular JK50S, heavy duty rotary valve arrangement, into the existing, unique, vertical scraper conveyor, this feeding an existing Biomass facility. The system has fully automatic, electronic level sensing, this in order to avoid unnecessary blockages and subsequent production down time.

The ducting system comprises of 2 independent lines, each with machine-controlled auto dampers to ensure the system only consumes energy when the machines are in use and explosion isolation valves for enhanced safety.

With Indusvent e-control, the high efficiency extraction fan will only run at the speed required, this depending on the number of lines that are open at any one time. The result of which means the customer is only paying for energy used, as and when required and have also created a much better working environment for operators setting up machines. With clean up points included at every machine as standard, this factory will be spotless without the use of brushes, which can re-introduce fine dust back into operators breathing zones, this resulting in secondary exposure issues.

All the above will be monitored using the Indusvent remote monitoring system, allowing us to keep an eye on your extraction system, while you are busy doing what you do best, if we spot anything worth talking about, we will send you a weekly update, all free of charge.

For full details of our remote monitoring system see link below: –

https://indusvent.com/remote-monitoring/

A great effort by all @team Indusvent, from planning right through to commissioning.

If you would like to know more about our Super Blower 90 filter range or are interested in purchasing a market leading, highly efficient extraction system, then please do not hesitate to contact us.

Email: mail@indusvent.com Call : 0333 9967 333 or visit our website: www.indusvent.co.uk