Project Details

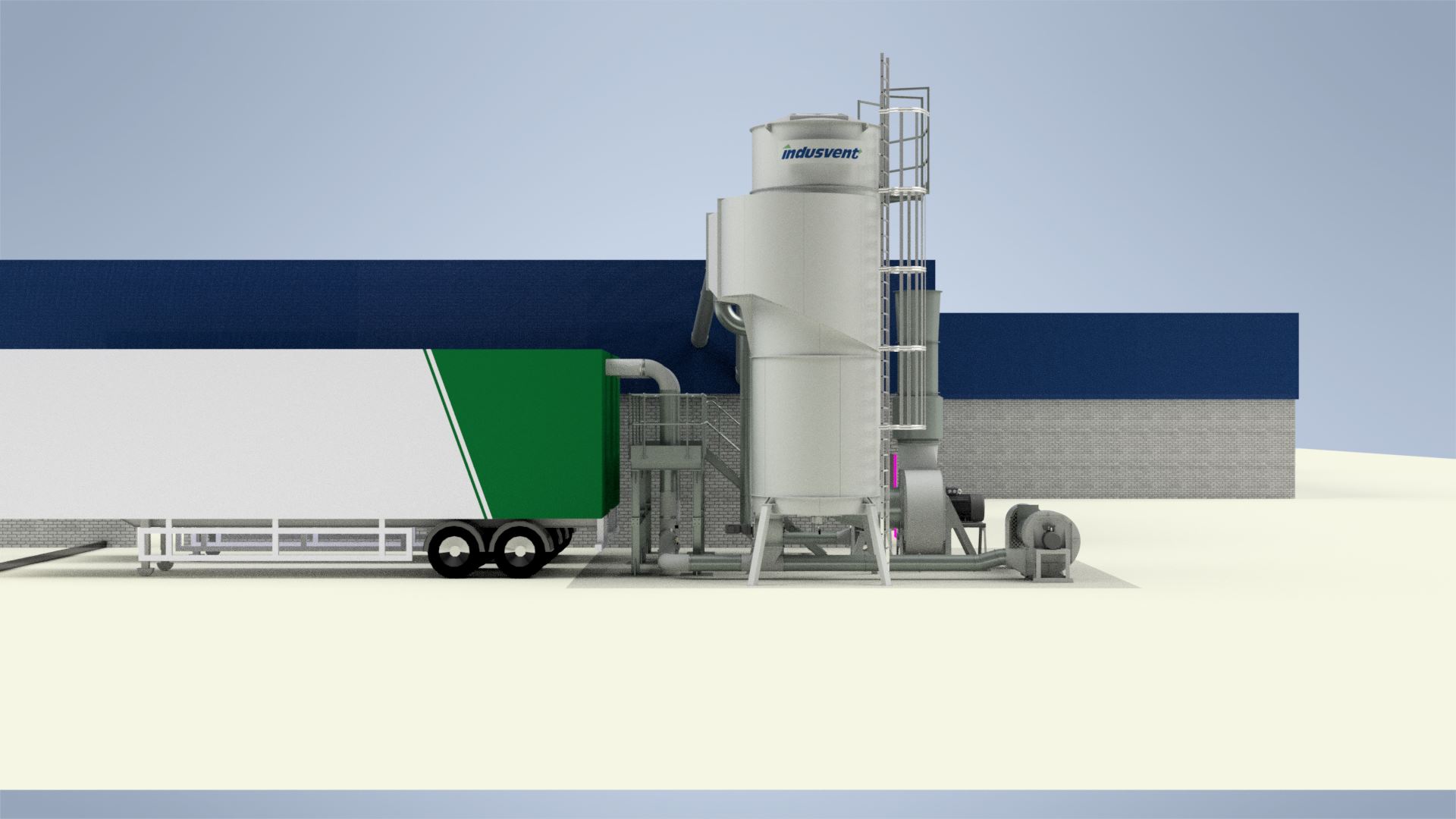

A leading provider of quality timber frames and engineered roof trusses in the UK, supplying both timber frame homes and commercial properties has made a significant investment in a state-of-the-art production facility in Ayrshire. When it came to selecting a dust extraction partner Indusvent were contacted at the very start of the project to work alongside the equipment manufacturer.

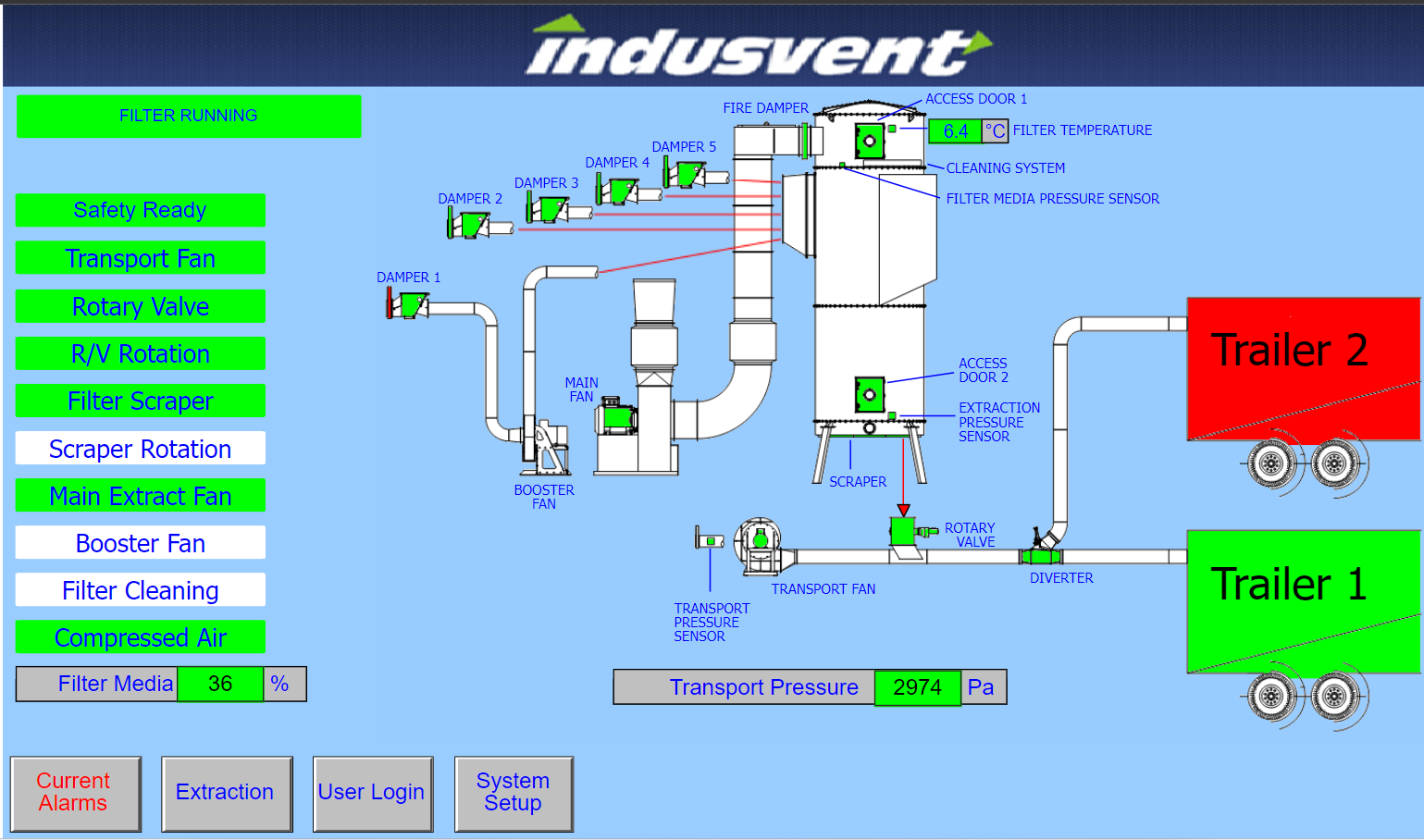

After a comprehensive study of the machine line, Indusvent suggested various modifications to the machine line capture hooding to reduce the static pressure requirement, this enabling a more efficient extraction level performance, ensuring a clean environment and workplace at a reduced energy level.

The system is now fully commissioned, both the customer and the machine supplier are extremely satisfied with the results, the machine manufacturer who undertake installations globally commented that the extraction performance is the best they have experienced.